Introduction

AN INTRODUCTion TO NAVAL MINES AND MINE WARFARE

SUMMARY

By Geoff Goodwin

Naval sea mines were first used by the Chinese in the 14th century against pirates and have been deployed in almost every maritime conflict since then. This included World Wars I and II, Korea, the Falklands and the Gulf Wars. An illustration of the simplicity and effectiveness of mines occurred in the Korean war when 3000 sea mines had been transported the length of the country by rail were laid at night by sampans, to block the harbour of Wonsan. The minefields caused a 250-ship amphibious task force with 50,000 Marines and soldiers embarked to be held off Korea’s East coast for two weeks until clearance operations were completed. The US Task Force Commander, Rear Admiral Allan E. ‘Hoke’ Smith, USN, observed:

“We have lost control of the seas to a nation without a Navy, using pre-World War I weapons, laid by vessels that were utilized at the time of the birth of Christ.”

Sea mines have increased in power and complexity over the years but remain a cheap and very effective weapon of war that is easy to use but difficult to counter.

SEA MINES

Sea or Naval Mines are underwater explosive devices designed to damage or sink ship or submarine targets. They are described in full in later sections but can be described in general terms as follows:

Buoyant Mines – moored or drifting; detonation initiated by contact or by the targets’ magnetic or acoustic signature.

Ground (Seabed) Mines – detonation initiated by the targets’ magnetic, acoustic or pressure signature.

Contact – means that the mine is initiated by contact with a target ship or submarine. Firing is achieved by switch horns, chemical horns or an antenna involving galvanic action.

Influence Mines – detonated by sensing a target’s magnetic, acoustic or pressure signature.

Controlled Mines - operated via a cable or an underwater signal and can therefore be fired at a time of the operator’s choosing.

Mine Fittings

Devices can be fitted to make countermeasures more complicated and for safety reasons:

Arming Clock - used to delay a moored mine from rising off it’s sinker or to delay the switching on of firing circuits in an influence mine for a period of time after laying.

Ship Count Mechanism - prevents the mine detonating or rising off it’s sinker until a certain number of ships or “influences” have passed over.

Mooring Lever - renders a moored mine safe if it breaks free of its mooring or is swept.

Hydrostatic Switch - can prevent the mine being in the armed condition unless it exceeds a certain depth. This is a safety mechanism but can be fitted as a firing switch to prevent the mine being recovered.

MINE LAYING

Mines can be laid (sewn) by surface ships, submarines or aircraft, depending on type and shape. Generally surface ships can lay any mine; submarines and aircraft lay ground mines.

MINE FIELDS

Mines can be laid offensively in areas where enemy ships are expected to operate, or defensively, to interdict enemy shipping approaching friendly coasts. A mine field may contain a range of mine-types and actuation systems to make countermeasures more difficult.

MINE COUNTERMEASURES (MCM)

Passive MCM.

Passive MCM are measures taken to minimise the effects of an enemy mine threat:

a. the use of a navigational warning system to inform friendly shipping of the presence of mines;

b. the controlling of friendly shipping to operate within routes and convoys, which reduces the area that has to be searched and cleared of mines.

Self Protective MCM

These are design and operating characteristics of ships and submarines that reduce the risks and effects of mines. They include: the fitting of magnetic coils to reduce magnetic signature (degaussing); transiting at minimum speed to reduce noise; using the deepest water; adopting a high state of readiness and watertight integrity.

Active MCM

A number of methods are used to find and dispose of mines:

a. Moored mines are swept by ships streaming wire sweeps fitted with cutters which cut through mooring wires. Swept mines can be sunk by gunfire or otherwise disposed of.

b. Influence mines, except pressure mines, are detonated, clear of shipping, by minesweepers towing either a magnetised cable or acoustic noisemaking devices that simulate ships’ signatures.

c. All mine types can be hunted by ships known as mine hunters using sonar. Disposal of any mines found is carried out using a remote controlled underwater vehicle or by divers.

d. Divers can be employed to dispose of mines located by sonar or by any other means and they can search and dispose of mines found in docks, harbours, anchorages and other areas. For these “clearance” diving operations the equipment used is especially designed to minimise sound and contains no magnetic material.

(Why do RN Divers hug mines? Answer here).

e. Recent developments in technology have made the use of autonomous vessels in MCM a feasible proposition and trials have been carried out. This reduces the risk to personnel and is likely to become an operational reality in the future.

MARITIME MINES AND THE LAW

The Hague Convention of 1907 sought to regulate the use of sea mines. Some modern states did not exist in 1907 and some others did not ever ratify the Treaty but NATO nations generally conform. The Convention covers such matters as the positioning of mine fields, publishing navigational warnings and mines being made safe when they break adrift or after a set period of time.

NAVAL MINES

by Captain Chris O’Flaherty Royal Navy

From “Naval Minewarfare: Politics to Practicalities” by Captain Chris O’Flaherty, Royal Navy. Abridged and very slightly amended by Geoff Goodwin. (The writing of this publication was partially funded by the Guy Hudson Memorial Trust).

‘Infernal Machines’

Naval mines are a pernicious weapon that use a combination of explosive shock and associated underwater pressure fields to generate damage in target ships. They achieve this through both shaking ships such that internal equipment is degraded or rendered inoperative and also, if close enough, through penetrating the hull, causing the target vessel to sink. However, these physical effects of an actual mine detonation are just the beginning of how mines really work as a weapon of war. The psychological effects of a naval or sea mine (the terms ‘naval mine’ and ‘sea mine’ are interchangeable) are often just as pernicious as these headline physical manifestations.

Naval mines are defined as:

‘munitions placed under, on or in the sea or inland waterway and designed to be detonated or exploded by the presence or contact of a person or vessel’.

They are categorised through their position under, on or in the water column due to buoyancy; their ability to move; and their method of detonation, explosion or actuation:

Buoyancy (and thus position):

Buoyant

Ground (i.e. seabed)

Mobility:

Drifting

Oscillating

Creeping

Homing

Anchored/Stationary

Actuation:

Contact

Influence (magnetic, acoustic or pressure)

Controlled

Figure 1 – Naval Mine Types. Credit: Andy Caputa

The final sub-classification for naval mines is actuation, or the mechanism by which the mine is made to explode. These can be broken down in to three simple groups.

The first and most common method of actuation is contact, whereby a vessel must touch part of the mine in order for the firing mechanism to function.

The simplest type of contact actuation is probably the switch horn, whereby a solid horn on the outside of the mine case is moved by the contacting vessel, making an electrical circuit which then fires the mine.

As technology advanced the Germans invented a simple chemically actuated mine in which a phial of acid is contained in a lead horn protruding from a mine case. Any ship that bumped into such a mine bent the external soft lead horn, shattering the internal glass phial of acid, allowing the acid to run onto two electrical contacts, thus forming a battery which electrically detonated the explosive. Such lead-acid horns are now one of the most widely used methods of naval mine actuation.

In order to extend the actuation radius of contact mines, some were fitted with ‘snag lines’ attached to their horns, such that a passing ship snagged a 20–30 metre length of rope attached to the mine’s horn, bending, pulling or twisting the horn and thus causing detonation.

As physicists developed their understanding of galvanic currents, science then allowed mine designers to extend further the actuation distance of contact mines by exploiting the phenomena whereby two dissimilar metals when in contact with each other in the presence of an electrolyte (such as seawater) cause a small current to be induced; by detecting and then amplifying the current generated when the hull of a steel ship or submarine brushed a copper antenna trailed away from a mine, the mine could be made to explode when targets were within a pre-set distance (the length of the copper wire). A mooring wire made of a suitable dissimilar metal could alos be used against submarines.

Many of the experiments associated with mine development required the actuation at a particular moment during a trial of an underwater explosive charge, normally triggered from a remote control station. Such remote control requirements led to another type of mine actuation known as controlled mines. The ability to control the moment of detonation from a distant location, such as a shore observation station, is not only valuable during periods of experimentation but also when laying defensive mines in areas where both enemy and friendly ships may transit. Remote control allows a minelayer to: actuate a mine when a ship is observed near it; place an otherwise dangerous mine into an inert state to allow the safe passage of friendly ships; or to place an otherwise inert mine into autonomous mode whereby the mine itself determines when to explode when an enemy ship is near enough to be damaged or deterred.

The desire to make mines explode when ships or submarines are simply near a mine, rather than actually in contact with it, led to the development, towards the end of World War I, of influence mines. Exploiting the properties of ships and submarines whereby various detectable phenomena radiate away from their hulls, the first influence mines initially actuated on the most easily (at the time) detectable of these – magnetic fields. That metal ships have a permanent magnetic field has long been known to mariners, who had to contend with the effect the ship’s magnetic field had on their magnetic steering compasses. Naval mine designers were thus able to install magnetic field detectors (such as magnetic coils) inside the casing of moored and then ground mines which would detect the changes in the earth’s magnetic field induced by passing vessels, thereby actuating or detonating the mine. Scientific advances combined with greater understanding of the small differences in magnetic fields around differing ship types and at differing distances allowed these early magnetic influence mines to be finely tuned against their intended target. However, parallel advances in mine countermeasures technology allowed navies to use long copper cables with large currents passing through them to mimic the magnetic signature of ships, thus causing simple magnetic mines to explode when a mine countermeasures magnetic cable was towed nearby, instead of waiting for their intended shipping target.

Mine designers then introduced a second actuation influence of acoustic ship detection, with simple hydrophones listening for the machinery or propeller noise of passing targets. This was, in turn, countered by mine countermeasures vessels towing underwater noise-makers which detonated these simple acoustic mines. Further development led to influence mines which combined both acoustic and magnetic influences, with one influence set to ‘wake up’ the mine and the other to ‘actuate’ it if it was detected within a pre-set time interval after wake up. Therefore, a passing minesweeper would have to be towing both acoustic and magnetic sweeps simultaneously – which was eventually achieved. The spiral of technological weapons development then moved a further step forward, with mine designers incorporating pressure sensors which detected the variations in water pressure that are obvious when looking at the large bow and stern waves of moving ships, and which radiate away from a fast-moving ship or submarine. Originally known as ‘oyster’ mines, such pressure mines are almost unsweepable, but fortunately were not deployed in large numbers before the end of World War II.

Modern influence mines exploit an even wider range of physical signatures generated by vessels, including acoustic, magnetic, pressure, seismic (the vibrations in the seabed induced by the propeller noise of a passing ship), underwater electric potential (UEP, or a stray-field electric current similar to galvanic currents), light (or shadow) as ships pass overhead of a mine, and many more. Influence mines have also been tuned to detect the presence of divers such that they detonate if approached by persons wearing magnetic or noisy diving equipment, or if lights from either divers or remotely operated vehicles are shone upon them. The list of potential mine actuation influences is now limited mainly by the ability of physicists to develop detectors capable of discerning the presence of nearby targets – either vessel or person.

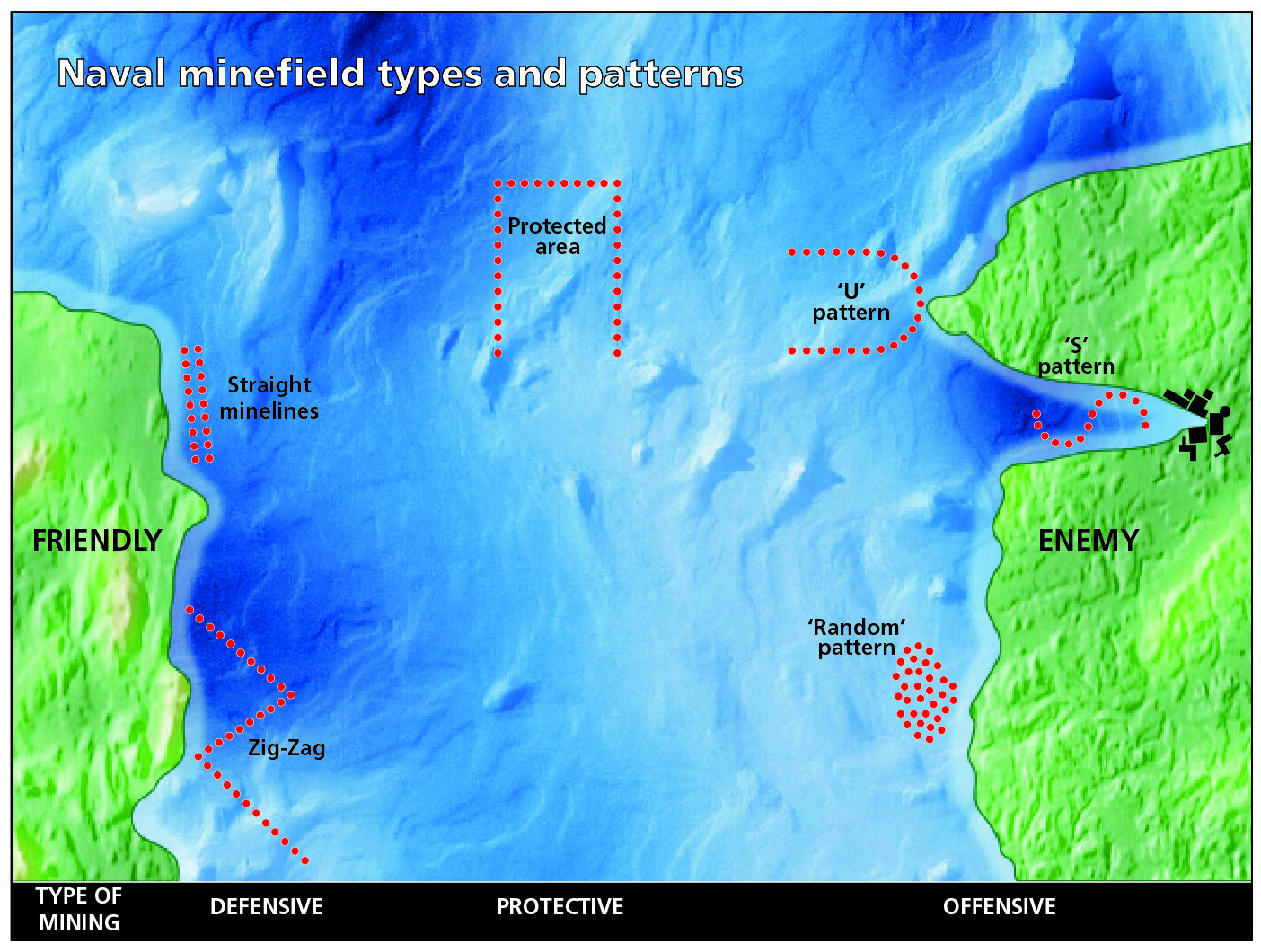

Minefield Types

In naval tactics there are three main types of minefield, determined by the location of the minefield relative to both own or enemy territory and also relative to one’s own shipping.

Based on academic definitions, the defensive minefield is generally laid in one’s own waters, or waters adjacent to territory held by one’s own forces. The aim of a defensive minefield should be to deny the enemy their ability to transit through your defences such that your forces are placed in a position of enhanced safety, noting that this applies to all forces and not just ships or submarines. Defensive minefields can be laid around ports and harbours as well as along beaches as anti-invasion minefields to protect land forces from amphibious attack.

A common characteristic of many defensive minefields is their simplicity, together with the care with which they are laid. It is important that the positions of defensive minefields are known to all friendly forces, that the mines within them stay where they are intended, and that if an enemy enters such a minefield they have a high probability of actuating a mine either to deter other attack forces or to receive sufficient damage so as to curtail their mission. Defensive minefields are also normally intended to remain in place for very sustained periods of time. Based upon the fact that their positions are known to defending forces, together with positional details of safe routes through which they can be transited, there is unlikely to be urgent pressure for their clearance on completion of conflict. To this end, defensive minefields are often densely sown with simple mines, including controlled mines.

Also designed to protect one’s own forces, but normally in a more expeditionary context, is the protective minefield. Often laid to exclude an enemy from a given area which is being used, or is about to be used, for high-seas marshalling by one’s own forces, such minefields are often more complex in their design. When designing a protective minefield the reasons for the desired defence, including any timespan for which it is needed, and the degree of required defence will become key planning factors that will affect the choice of mines, where they are sown, and their density. The target vessels, depth of water, size of area and ability of one’s own forces to actually achieve a minelay (potentially in the face of enemy resistance) will all play into operational planning. As this book will examine later, the political and strategic messaging associated with the conduct of such mining will also need to be taken into account. Protective minefields can also be used to separate opposing forces, creating a standing maritime barrier between two navies that may be subject to de-escalation or peacekeeping efforts by others.

Due to the range of factors involved in their design, protective minefields are often the most complex type of minefield. They can use a wide variety of naval mines including ground and moored, influence and contact, but, due to their range from a safe place for a control station, usually not controlled mines. However, the use of controlled floating mines is an option, albeit one which could cause considerable confusion if a friendly warship spots such a mine; is it definitely yours?

As a weapon of war, the laying of mines in an attacking manner is known as an offensive minefield. The strategy behind such minefields can vary from specific requirements to try and destroy specified vessels, to more broad requirements to deny an enemy his ability to exit his ports. The nature and location of offensive minefields often makes them the hardest type of minefield to lay, in most cases requiring aircraft or submarines to act as the mine-delivery platform. This slightly limits the variety of mine types that can be used.

The offensive minefield is often the most strategically significant. By its nature, offensive mining is an aggressive action usually undertaken in enemy-held waters and creating an often very persistent threat. It is thus likely to require careful consideration at the most senior levels of government. High density offensive minefields may be deployed with the primary intent to maximise damage and sink enemy units through the kinetic warhead of each mine, with lower density offensive minefields (sometimes referred to as ‘harassment’ minefields) maximising the potential of the psychological warhead to achieve their effects. The location of offensive minefields may also drive post-conflict levels of urgency to clear those mines, which may also be a planning factor when determining which types of mines to sow.

Within minefields various patterns may be used for naval mines. The most common, based on development of the minelaying ship, is for mines to be laid in minelines whereby moored or ground mines are laid in geographically straight lines with predetermined spacing between mines driven either by: the number of available mines versus the size of area to be mined; the required level of threat; or, as a minimum, the smallest practicable distance between explosive warheads required to prevent sympathetic detonation of adjacent mines.

Minelines may also contain angular turns or zig-zags, inserted when the laying ships change their course during laying. This creates a pattern of mines whereby a transiting ship cannot pass through a mined area on one course, directly parallel to any straight minelines, without causing mine actuation. Minelines may also be curved, such as when ’S’-shaped minelines are laid along rivers and channels, allowing the minelaying ship to weave along the full width of a navigable channel whilst remaining, itself, in navigationally safe waters. Or they may be ‘U’ shaped, such as off a headland, thus creating a situation in which a target ship navigating around the headland has

to cross the mineline twice (thus increasing the probability of it actuating a mine).

The second type of moored and ground mine distribution looks to the naked eye as being ‘random’. Generally, however, such apparently random patterns within a mined area are often carefully calculated to ensure any target ship passing through the mined area has a given probability of actuating a mine. Such random minefields are easier to lay from aircraft and are generally harder to counter.

Figure 2 – Naval minefield types (per academic definitions) and patterns. Credit: Andy Caputa

Mine Technology

Driven by both the types of mines available for use and the objectives for which they are to be deployed, mine designers have incorporated an assortment of subtle features into their mines. These can either enhance the ability of mines to achieve their desired effect against intended targets (selected from the broad variety of shipping present in many areas of the world), or they can mitigate against minesweepers clearing their mines before they can have their intended effect (discussed in the next chapter).

A significant design consideration is that of the charge weight, or how much explosive is required in different types of mine. Early 18th-century mines contained between 35 and 70 kilogrammes of gun cotton or gunpowder, which caused sufficient direct explosive shock so as to puncture a wooden ship’s hull when detonated in direct contact. The advent of the ironclad required a minewarfare response whereby explosive charge weights were increased to levels required to puncture a (potentially reinforced) metal hull. The balance that was required in the 19th century was thus between sufficient weight of explosive countered by the buoyancy required to maintain these heavier explosives in the water column, which in turn required ever larger and more unwieldy mine cases which had to be transported to sea and be laid. The introduction of moored-influence mines which are detonated when close to, but not necessarily in contact with, the hull of the target required further increases in explosive effect. By 1945 some moored mines contained explosive-charge weights of up to 300 kilogrammes, which is probably the largest practicable size for moored mines and which will inflict substantial damage to the underside of just about any ship that is sufficiently close.

The advent of controlled mines, which often involved the detonation of an explosive warhead remote from the hull, required further increases in charge weight. Some controlled mines remain of the moored-contact type, which means they can contain appropriately small charge weights. However, any mine that is intended for detonation more than 2 or 3 metres from its target requires substantially more bang to create a damaging effect.

Moored-influence mines are constrained explosively by the buoyancy requirement mentioned above. In contrast, ground mines are unencumbered by the requirements of a positively buoyant minecase allowing substantially more explosive to be built into them. Such ground mines can then make use of both explosive shock (as used by contact mines), and also of the ‘bubble’ effect created by an underwater explosion. Specifically, when an explosive is detonated underwater the solid explosive material transforms into a gas which occupies a much greater volume. This gas is itself buoyant and so travels upwards towards the surface, expanding and contracting due to pressure differentials, following behind the initial shock wave created by the explosion. Thus, a ship directly above a ground mine receives two hits; the explosive shock wave followed shortly afterwards by the upwards impact of a huge gas bubble. The gas bubble has upwards velocity which can initially give slight lift to a ship’s hull, but which then immediately generates an area under the ship with no water, thus no buoyancy, thus no support for the hull (as per Archimedes’ principle) which falls downwards into the void. The gaseous void is then refilled by an inrush of water, providing buoyancy which re-lifts the ship a further time. This violent and repeated upwards-downwards motion quite literally shakes the ship apart, causing substantial damage to internal machinery as well as to people who are being thrown about inside the steel box of the hull.

To create this bubble effect requires as much explosive as is practicable. Many years of both trials and of operational use have shown that against small vessels in very shallow water charge weights of as little as 30 kilogrammes are sufficient. Against larger vessels in deep water charge weights of up to one ton are required for ground mines to be effective, reaching their operational limit when in water depths greater than about 80 metres, which is when the distance between the explosion and the target becomes so great that the combination of hemi-spherically reducing explosive shock and the upwardly expanding bubble becomes insufficient to be effective against a surface ship.

The weight of explosive is often only part of the issue; there is also the composition of the charge. Early mines used a relatively unstable explosive known as guncotton (nitrocellulose), or similar low-yield explosives. The advent in 1867 of Trinitrotoluene (TNT) reduced the inherent risks of a relatively unstable explosive, but at the cost of about 10 per cent of the explosive yield for a given weight of charge. Recent advances in chemistry have further reduced the risks of unintended detonation due to chemical instability whilst concurrently increasing the explosive yield. By World War I, the explosive Amatol (a combination of TNT plus ammonium nitrate) had restored the explosive yield back to the same as guncotton, but without the risk of explosive instability. By the middle of World War II, the explosive Torpex (a nitramide combined with TNT and powdered aluminium) had increased by 50 per cent the explosive yield of mines for a given weight, with further advances in explosive chemistry allowing some modern mines to deliver twice the explosive force as earlier models of similar weight. Thus the mass of a modern mine charge is not directly proportional to the TNT-equivalent explosive yield.

A further design consideration is the effect required from the mine. If the desired effect is damage, such chemistry and mathematics are a crucial part of minefield planning. In contrast, if the desired effect is the psychological creation of fear, then the very presence of a mine explosion – any mine explosion – may be sufficient to achieve mission success. The same creation of fear may be achieved if viable mine cases are exposed (and seen by the enemy) at low tide. It is conceivable that the some effect may be achieved by the formal international declaration of a non-existing mine field.

Modern technology in mining goes beyond the mathematics and chemistry of the explosive. Methods of detecting the presence of a ship can be augmented by technological features such as ship-counts, which allow a mine to be set such that it ignores the first few ships it detects (which may be minesweepers) before detonating under high-value maritime units further into a convoy. Or the increasing prevalence of relatively cheap micro-electronics may be used to refine exactly which elements of a vessel’s unique acoustic signature actuates a mine, thus allowing mines to be targeted against specific types of ship, or even individual ships.

In parallel with counting the number of passing ships, internal clocks can be used to delay the time a mine arms itself after being laid, allowing neutral ships to be told to leave a port before a minefield becomes active. Such clocks can then be used to deactivate a mine completely after specified periods or on a given date. Circuits can also be set such that the mine self-destructs at a specified time in order to render it harmless. Alternately, in the case of buoyant mines such rendering harmless, or sterilisation, can be achieved by the clock activating a ‘flooder’ that creates a hole in the mine’s buoyant case causing it to sink to the seabed, or in a ground mine clocks can simply cause the electric circuits to shut down.

Sterilisation can also be achieved by more mechanical methods, such as a ‘mooring lever’ on the base of a moored mine. Such levers use the cable tension created between the buoyant mine case and the heavy anchor to keep complete the electric circuit allowing the mine to actuate as designed; but when the mooring tension drops – either when a mine breaks free from its mooring or when swept by a minesweeper – the mooring lever moves and interrupts the mine’s firing circuit, thus sterilising the mine. Modern through-water acoustic technology can also aid sterilisation, with mines ‘ordered’ to either self-destruct or deactivate when they receive a pre-programmed acoustic message.

The limits of affordable technology continue to be explored by mine manufacturers. Some modern mines now include drifting models equipped with satellite telephones and Global Navigation Satellite System (for example, GPS) receivers with mines remaining active when floating and drifting in a specified geographic area but which then deactivate either when telephoned by their shore control station or when their navigation system indicates they have left their patrol box.

The range of possibilities of how to actuate or manage minefields thus seems limited only by a combination of the boundaries of maritime physics, the imaginations of mine designers, and the amount of money purchasers are willing to pay.

Present Situation

At the time of writing it is estimated that about fifty states maintain stocks of mines. But this figure can change quickly because the global proliferation of mine technology, ease of manufacture of the most simple types of mines, and ease of employment of many mine technologies by people with only limited training, making naval mines an attractive weapon option for navies to acquire cheaply and at short notice.

Many of the developments in mine technology and mining tactics described above have been driven by the cat-and-mouse game between minelayers and those tasked with dealing with them – the sailors and airmen of mine countermeasures forces. As techniques have been developed to deal with mines before they have achieved their intended effect, so mine designers have responded. The spiral of mine; mine countermeasure; counter-minecountermeasure etc. has been going on for over 200 years and continues today.

See a short film about Naval Mines here.

NAVAL MINE COUNTERMEASURES

‘A group of ships [mine]sweeping . . . carr[y] on their warfare at the same tactical speed as that used by Sir Francis Drake’

The threat generated by any military weapon requires a reaction by enemies in order to overcome, or at least mitigate, the threat posed. In the case of naval mine countermeasures, the many counter-mine systems developed over the 200 years of modern minewarfare offer a fascinating tale of cunning and innovation required to reduce the risk from, or effect of, these infernal engines of war.

Mine countermeasures, often abbreviated to MCM, began with sailors pushing drifting mines away from their ships. This early MCM used wooden poles which sailors hoped would be long enough to keep them safe if the mine detonated as a result of an overzealous shove against the mine case. Nets and other barriers were then laid to keep early drifting mines away from anchored ships, until the threat from mines moored in channels required new measures that were instead effective when ships were underway. In the American Civil War counter-mine ‘rakes’, elaborate contraptions which looked literally like a huge garden rake, were lowered before the bows of ships as they sailed through threat areas, detonating mines a few metres ahead of the vessel but far enough away that the still relatively small explosive charge did not cause damage.

In the early 20th century the evolving threat from mines vexed ship designers who developed elaborate attachments for ships of varying sizes designed to either push buoyant mines away from the hulls of ships, or to detonate them at a safe distance from the hull. Paravanes, pulling minesweeping wires, were fitted to the bows of battleships, but required the ship to keep moving in order for them to remain streamed. New developments of Ollis Gear, Campania Gear, Exmouth Gear, Raglan Castle Gear and Cock’s Gear (for trawlers) then became variations on the theme of fixed protection mounted on the bows of ships of various sizes, each proving to be successful but reliant on good seamanship (and time) to deploy and recover.

Such fitments to ships, as well as internal measures such as closing watertight doors and keeping a good lookout for floating objects, became known as Self-Protective Measures and still form a core of modern mine countermeasure methodology.

In order to overcome the restrictions in mobility posed by such cumbersome devices, methods to positively clear moored minefields were developed. At first these involved the dragging of heavy wires along the seabed in an attempt to snag-and-drag the moorings of mines. But such mechanical minesweeping methods involved the exposure of the towing ships to the full risk of the mines, driving the assignation of certain small, cheap, expendable, shallow-draught vessels to the role of mine countermeasures. By the late 19th century the trawling techniques of fishermen were being adapted to mine clearance, with wires in mid-water fitted with mooring-cutters being towed behind small ships, as well as similar devices being fitted to the bows of larger vessels to give them added protection. But the seabed sweep still had utility as a method of cutting the cables of controlled mines, often in preparation for an amphibious attack.

The development of influence mines, initially magnetically actuated followed by acoustic then pressure, required a change in methodology. Instead of towing wires to cut mooring cables, wooden minesweepers started to tow huge magnets, with the low magnetism of wood allowing (hopefully) these small influence minesweeping vessels (and later, aircraft) to pass directly over magnetic mines with their tows mimicking the signature of a much larger vessel to detonate any mines. This was truly nerve-tingling stuff! Acoustic mines required the (often simultaneous) towing of large underwater noisemakers or loudspeakers, generically known as acoustic generators. However, the advent of pressure mines introduced a problem that could not be solved by smaller ships – the pressure signature of a vessel is directly proportional to size versus speed.

More novel forms of mine countermeasures were also developed, including a German technique known as a Sperrbrecher, in which a larger ship is reinforced structurally and with an enhanced magnetic/acoustic signature to allow it to literally punch through a minefield, detonating everything in its path.

The invention in 1918 of active sonar, followed by significant development during World War II, offered a new possibility; instead of towing the methods of dealing with mines it was now possible to look for mines ahead of mine countermeasures vessels. After limited success during World War II using anti-submarine sonars to look for naval mines, this significant safety enhancement led to the development in the 1950’s and 1960’s of the minehunter. Initially such minehunting ships were also fitted with minesweeping equipment, but many are now a distinct class of vessel. Other developments in the sciences of chemistry and physics, allowing effective detection of mines using such esoteric methods as magnetometers or explosive-sniffers, have further increased the safety of those sent into minefields to clear them. The development of minesweeping helicopters also allowed increases in safety, with the towing vehicle now far enough above the threat so as not to actuate it. And in one particularly novel development, marine mammals, such as dolphins, were trained to find and mark mines for divers to subsequently approach and dispose.

The most modern technologies now centre on the use of remotely controlled or autonomous underwater and surface vessels transporting sonars and magnetometers into suspected minefields or towing influence minesweeps through potentially mined areas. Such vehicles are sometimes referred to as ‘unmanned’, but are more accurately referred to as ‘remotely manned’ as all require significant levels of manpower to program, prepare, deploy, recover, analyse and repair; their advantage is that fewer people are actually exposed to the risk of operating in the heart of any naval minefield.

The challenge thus posed is a choice of which system to use in which circumstances, which often involves investment decisions taken many years ahead of a known conflict. The panacea may be seen as the use of technology, such as sonar, to reduce the risk to mine-clearance personnel whilst also reducing the risk to other shipping. But the limitations of science then starts to rear its head by presenting a plethora of uncertainty in the minewarfare battlespace.

Minehunting is one such science-based system. This is the use of specialist technologies to create images of the water column and seabed in order to detect underwater objects, classify them as mine-like (or discard them as non-mine-like), positively identify each one as a naval mine (or not, such as a rock or pipe), and thereafter to neutralise all mines so that they no longer present a threat to shipping. This detect-classify-identify-neutralise process is known as minehunting’s detect-to-engage sequence.

This process of minehunting is complicated by a host a variables, including the fact that the sea is opaque, thus visual searching is often not effective in anything but the shallowest of clear waters, requiring sonar to be used to image the seabed. However, this sonar is not completely effective at searching due to environmental factors including water temperature, salinity, seabed absorption and reflectivity. Precise details about the threat, such as its size and sonar reflectivity, are added to equipment and operator performance before moving onto variables such as mine burial on impact with the seabed (during laying) as well as subsequently by seabed currents disturbing nearby sediment causing ‘scour’. Having detected an object, the classifying of it as a possible mine, or not, is complicated by the myriad of seabed detritus that resembles the wide variety of potential mine shapes; this leads to many objects being classified as a ‘possible mine’ despite being nothing other than a hemi-spherical rock or an old pipe. Opaque underwater visibility can denude the effectiveness of underwater cameras or laser systems despatched to identify potential mines, although the touch of a well-trained diver can mitigate such constraints. Almost all of these factors can be measured and given numerical values, which are then fed into doctrinal and decisional models, but these values can change throughout a minehunting operation mile by mile, or even metre by metre, greatly affecting the effectiveness of the detect-to-engage sequence. Of necessity averages and approximations are used, requiring the art of MCM to determine their relative significance and thus how often re-planning or changes to tactics are necessary in order to maximise the chances of success in a timely manner.

A useful analogy for minehunting is that of searching a room for an object(s). We cannot see clearly underwater, so assume the lights in the room do not work (and there are no windows); we don’t know if the object is actually in the room or not – military intelligence only gives us an indication; if the object(s) are in the room we are searching, we do not normally know how many there are; the room may not be clean, so as well as our desired object(s), there may be similar object(s) to confuse or delay us; the floor of the room may not be solid, so some of the object(s) may be partially or wholly buried (undetectable); and the searcher may be fatigued, so not wholly effective. Thus, the best we can do when we eventually emerge from the room is to generate probabilities that we have searched correctly and found what we should. The sea is exactly like the room described above – often soft-bottomed, opaque, littered with shells, rocks and debris. Technology may help optimise the search, but it is not definitive.

The variety and novelty of the various countermeasure methods and variables above introduces a problematic triad for mine countermeasures: time, risk, and resources. Mine clearance takes time, often lots of it. MCM has a law of diminishing returns whereby doubling the search effort does not halve the risk of missing a mine – it changes logarithmically. In consequence, much of MCM is a balance between how long you wish to commit a finite set of MCM resources to a given task, and thus the risk you end up with, and prioritising what risk you require as your outcome, which then drives how long a task will take for given resources. This drives a key factor in the art of MCM – the balance between time and risk; you cannot take forever, but you must avoid being too hasty.

Genres of Mine Countermeasures

An aim of mining is often to deny the use of an area of sea to an enemy through creation of fear. A key aim of mine countermeasures is, thus, to maintain or regain the use of sea areas through reducing fear by mitigating the threat from mines. The limitations of MCM resources require decisions to conduct such missions to be carefully targeted and, where possible, to focus resources where they maximise their contribution to the overall mission. Why do you want the access? For which forces? When? And to what level of risk? All warfare involves risk, and minewarfare is no different.

The conduct of operational MCM can be broken into two genres, each with two facets. The genre of passive mine countermeasures encompasses those actions taken to minimise or mitigate the threat from mines through measures that do not interface directly with the mine itself. They are a states’ or navies’ general, campaign- and fleet-wide, actions to reduce the risk from mines. The counterpoint is the genre of active mine countermeasures which sets out those positive measures and actions that reduce the risk from enemy mining through direct interaction with enemy mines themselves, normally using specialist forces.

Each genre has two facets: offensive mine countermeasures, which are orientated towards the enemy and generally focus on stopping mines being laid; and defensive mine countermeasures, which relate to the actions taken to reduce the threat to one’s own ships once the threat from mines is imminent or is realised due to them having actually been laid. The totality of actions within these areas forms ‘Whole Spectrum MCM’.

Passive-offensive MCM starts well before the kinetic or shooting phase of any operation. The soft power of diplomacy, Information Operations, industrial espionage (for example denying the enemy the ability to acquire mining technology), weapon-import sanctions and international legal argument, can all be used to dissuade an enemy from acquiring and using naval mines. A powerful passive-offensive MCM tool is the use of naval suasion within activities of statecraft led by the diplomatic instrument, for example the forward deployment and publicising of a credible mine countermeasures force.

Non-kinetic measures not interfacing directly with naval mines can also be taken within one’s own organisations. A state being threatened by mines, or that could in the future be threatened by mines, will want to prepare elements of a credible MCM force. Such preparations may include both standing military MCM forces and reserve MCM forces; throughout history the resources devoted during conflict to countering mines have needed very significant augmentation, with the professionalism of civilian fishermen proving to be especially beneficial in such activities as military minesweeping. The modern transition to sonar-based mine countermeasures may now add to this national talent-pool of people such as hydrographers and oceanographers. Thus, the maintenance of registers of suitable augmentation shipping, personnel and civilian-equivalent equipment (such as unmanned underwater vehicles, or UUVs) should be seen as a passive-defensive MCM enabler.

Long-term counter-mine planning can start when procuring non-MCM military shipping, by incorporating design features such as low acoustic emissions and degaussing to reduce their magnetic signature. As the threat from mining increases, the activation of a mine-spotting organisation around one’s coast can be combined with activation of pre-planned tactical routing designed to use depth or oceanography to reduce the risk from mines.[1] Such passive-defensive measures can also be accompanied by the issue of comprehensive counter-mine guidance to companies and ships (civilian, military, specialist and general), greatly mitigating the overall threat from mines. A comprehensive list of such passive-defensive measures, focussed towards civilian requirements, is detailed at Annex A.

The correct employment of such passive-defensive measures can be a critical enabler for the continuation of commerce, which is a vital parallel to the military activities often more closely associated with operations involving naval mines. Many passive-defensive measures can be implemented at relatively low financial cost, but such implementation can be significantly eased by prior preparation of appropriate plans and information sets (such as pre-designated routes, pre-determined mine-watch surveillance locations, or knowledge of which ships have the least susceptibility to naval mines). The relatively small investment by ports, shipping lines and ship masters in such preparations can be repaid many times over by those organisations not only becoming preferred commercial partners in countries under threat of naval mining, but also by those organisations becoming the only commercial entities that can profit during trading periods otherwise interrupted by naval mines.

Active-offensive mine countermeasures attack the enemy network that designs, manufactures, distributes, loads and lays enemy mines. In other words, all potential actions to stop enemy mines from entering the water. Due to the potential effects of enemy mining on all aspects of military operations as well as the economic health of a target country, active-offensive MCM can be a strategic-level mission. Kinetic activities to disrupt or destroy enemy mine stocks before they are laid can include bespoke military action, special forces action, amphibious raids or the aerial bombing of mine warehouses. Dependent on enemy vulnerabilities, this supply-chain disruption can also utilise cyber techniques or active industrial espionage to affect adversely the mine-manufacture process. Once mines have departed the supply chain and have been prepared for laying, kinetic action to defeat them becomes integrated with Sea Denial and Air Superiority activities, with surveillance of potential minelayers (including aircraft) being combined either with attacking (and destroying) them whilst their mines remain onboard, or surface-ship minelayers being boarded and seized with their payload of mines still intact.

Such kinetic disruption of future minelaying may also rely on information obtained through the exploitation of previous minelaying or mine seizures. Achieved primarily through Mine Investigation and Exploitation (MIE), the importance of attacking an enemy’s network which underpins their naval mining efforts cannot be underestimated.

Mines are a lot easier to deal with before they have entered the water, and exploring all sources of information to aid this objective is a fundamental part of naval mine countermeasures.

Should these measures fail to prevent enemy naval mines being laid, or should reasonable suspicion be generated that enemy mines have been laid, active-defensive mine countermeasures are designed to mitigate the risk from mines that have been sown. The key nuance in this sentence is that, ideally, such active-defensive measures should defeat enemy mines, but the factors affecting the conduct of defensive mine countermeasures – the balance between time, risk and resources – mean that delivering a comprehensive defeat of enemy mines borders on being unachievable. Threat mitigation and risk reduction is the best that can be achieved.

The two main methods of active-defensive mine countermeasures are minehunting and minesweeping. As already described, minehunting involves the use of sensors, such as lasers, sonar or magnetometers, to detect mine-like objects either in the sea or on the seabed, allowing other sensors such as remotely operated vehicles equipped with cameras to identify such objects as mines (or not). Then disposal systems such as clearance divers or autonomous underwater weapons can destroy the mine. Although slow, generally occurring from ships moving at between 1 and 4 knots, minehunting is generally considered the safest method of active-defensive mine countermeasures due to the search phase taking place ahead of, or remote from, the mother ship. The number of people thus exposed to the mine threat is reduced to the minimum required to achieve the mission, if indeed any people are required in the minefield at all. Whilst divers were an integral part of the identification and disposal phases of early minehunting systems, the adoption by navies of improved remotely operated vehicle technology has reduced this requirement in many cases. Paradoxically this removal of divers often occurs in all but the most hazardous of situations such as zero underwater visibility, where the ability of divers to use touch to identify objects has yet to be replicated. The standard minehunting cycle of ‘detect-classify-identify-neutralise’ when utilising divers also contains flexibility for it to be adjusted for a mine to instead be rendered safe and recovered for forensic examination and intelligence exploitation.

The other primary method of mine clearance is minesweeping. This method is the iconic image of minewarfare forces, generated by the brave personnel of two world wars who towed heavy wires through minefields to cut the cables of moored mines,[2] or who towed huge magnets and acoustic generators through influence minefields to simulate larger ships. Moored mines that are cut then float to the surface, where they can be either recovered or destroyed, with influence mines being deliberately destroyed by actuation. Much faster than minehunting, generally occurring at about 8 knots (although ‘Fast Fleet Minesweepers’ of World Wars I and II swept at up to 22 knots), of significance is that in both cases of sweeping the mine-clearance system is towed, not pushed, thus the personnel in the mine-clearance vessel are fully exposed to the threat, mitigated only by their modern low-signature ships and their own diligence. Minesweeping by helicopters negates this risk to vessels, and remotely manned ships can negate the risk to personnel, but due to cost these systems are only available to some nations.

In some circumstances, technology becomes limited by very shallow water-depths, turbulence, or the amount of seabed clutter (non-mines) that confuse technological systems. In such circumstances visual search is required, usually conducted by clearance divers wearing specialist breathing apparatus that emits neither noise nor magnetic influence, allowing them to swim up to both contact and influence mines to identify and dispose of them.

These active-defensive mine countermeasure methods have generated within the minewarfare community a useful maxim, related to safety but cognisant of time:

Hunt where you can; Sweep where you must.

Unmanned where you can; Manned where you must.

[1] Such tactical routes are known in NATO parlance as ‘Q-Routes’.

[2] The most common method of mechanical minesweeping in Western nations is known as the ‘Oropesa Sweep’; so-called after His Majesty’s Trawler Oropesa, used by the Royal Navy in 1919 as their trials ship to develop minesweeping equipment and techniques. Although upgraded in World War II with new wire-cutters, the 21st-century minesweeping system used by hundreds of the world’s minesweepers would be instantly recognisable to the original trials team. This ‘Oropesa’ technology is now a century old, and still works.

Find out more about modern Minesweepers, Mine Hunters, Diving Teams and ongoing operations here.